Tom.Diekhaus

Civil/Environmental

- May 21, 2025

- 1

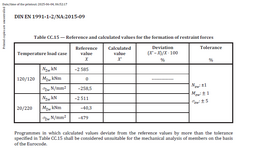

For my studies I should create a model from the DIN EN 1991-1-2 with the program Abaqus. The model (Annex CC Example 7) observes the stress results through thermal expansion in a fully restrained rod at both ends. The temperature fields should be defined at the top surface and the bottom surface of the model. For the first case of the model the temperature at the top and bottom surface should be 120°C. The resulting forces should be a Normal force of 2585 kN and a stress of 258.5 N/mm2.

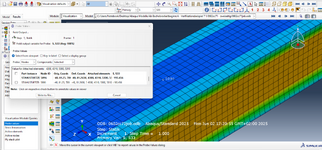

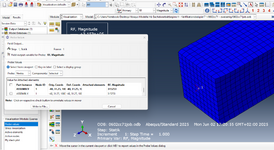

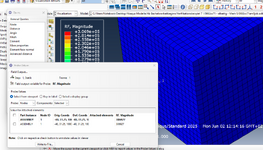

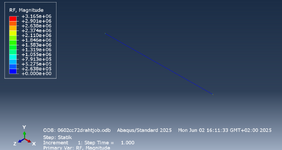

For the model I used the Static, General Step in Abaqus. The temperatures are defined at the top and bottom surface through predefined fields. The supports are fully restrained (U1, 2 and 3;UR1, 2 and 3) and defined to a reference point. The reference point is defined at the surfaces at the end through rigid body constraints. The mesh is defined as 10. The used units are Newton and millimeter [SI (mm)].

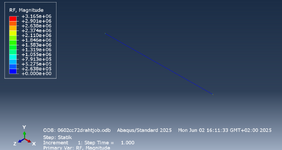

The results of this model dont fit with the the ones of the example. The maximum stress (S33 in this model) in the middle of the rod is around 200 N/mm2, the Normal force (observed through the Reaction Force at the Reference points) results in around 315 kN.

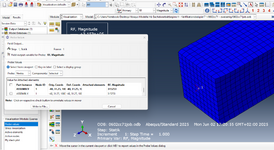

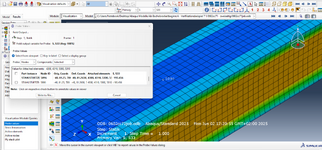

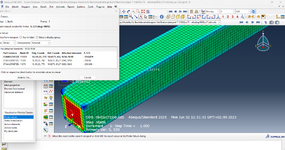

In a second model I defined the temperatures at all surfaces in longitudinal direction. In this model I got stress results quite similar to the ones of the example at the edges of the rod. However the Reaction Forces still didnt match but were much higher.

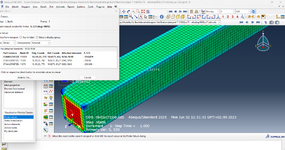

After that I used a different Mesh for the model (Mesh 5) which gave me much lower reaction forces. On the other hand I also defined a Wire model with the same temperatures which gave me much higher results. Still both models didnt match the example.

My questions are:

Why are the reaction forces of the models so different, why are the results not fitting to the ones of the example in the Eurocode and is it right to define the temperatures at all surfaces or only the ones at the top and the bottom?

For the model I used the Static, General Step in Abaqus. The temperatures are defined at the top and bottom surface through predefined fields. The supports are fully restrained (U1, 2 and 3;UR1, 2 and 3) and defined to a reference point. The reference point is defined at the surfaces at the end through rigid body constraints. The mesh is defined as 10. The used units are Newton and millimeter [SI (mm)].

The results of this model dont fit with the the ones of the example. The maximum stress (S33 in this model) in the middle of the rod is around 200 N/mm2, the Normal force (observed through the Reaction Force at the Reference points) results in around 315 kN.

In a second model I defined the temperatures at all surfaces in longitudinal direction. In this model I got stress results quite similar to the ones of the example at the edges of the rod. However the Reaction Forces still didnt match but were much higher.

After that I used a different Mesh for the model (Mesh 5) which gave me much lower reaction forces. On the other hand I also defined a Wire model with the same temperatures which gave me much higher results. Still both models didnt match the example.

My questions are:

Why are the reaction forces of the models so different, why are the results not fitting to the ones of the example in the Eurocode and is it right to define the temperatures at all surfaces or only the ones at the top and the bottom?