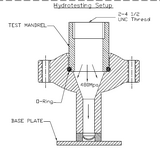

I have an o-ring piston seal application where the only special part is the pressure is extremely high.

DP: 69,620 psi at room temp

Seal Bore dimensions are flexible, as is the surface finish.

Backups will be needed that remove the extrusion gap and will handle the load. May have to be metal backups.

The test only needs to be held for approximately 20 seconds. to plot a straight line and show it saw pressure.

A small leak may be tolerated if it can be shown to be the only leak.

What kind of seal is used for ultra-high pressure?

Maybe I could use the flange and attach a Gasket and compress it using bolts?

Test fluid hydraulic oil or water. Havent thought about the fluid.

What's the limit of an elastomer seal with plastic back-ups? 40,000 psi?

Can anyone steer me in the right direction ?

I've had all the major seal companies like Parker and Greene Tweed decline (probably because the yearly usage is too low)

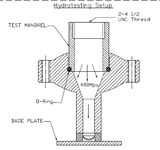

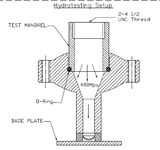

DP: 69,620 psi at room temp

Seal Bore dimensions are flexible, as is the surface finish.

Backups will be needed that remove the extrusion gap and will handle the load. May have to be metal backups.

The test only needs to be held for approximately 20 seconds. to plot a straight line and show it saw pressure.

A small leak may be tolerated if it can be shown to be the only leak.

What kind of seal is used for ultra-high pressure?

Maybe I could use the flange and attach a Gasket and compress it using bolts?

Test fluid hydraulic oil or water. Havent thought about the fluid.

What's the limit of an elastomer seal with plastic back-ups? 40,000 psi?

Can anyone steer me in the right direction ?

I've had all the major seal companies like Parker and Greene Tweed decline (probably because the yearly usage is too low)