Within cities, this condition is very common. The 10" foundation wall sits on the edge of a 24" to 30" footing. Almost always this overstresses the allowable soil bearing pressure provided by the geotechnical report (via straight calculation).

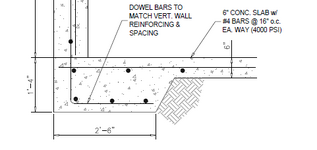

What are your thoughts on tying the slab into the footing to help disperse the building loads? 4" slab, use #4 rebar @ 16 instead of wire mesh?

What are your thoughts on tying the slab into the footing to help disperse the building loads? 4" slab, use #4 rebar @ 16 instead of wire mesh?