waveformeng

Structural

- Jun 19, 2025

- 2

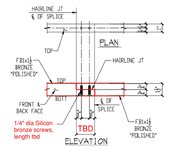

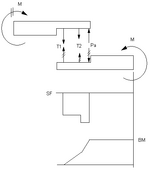

I have a solid rectangular steel plate subjected to shear and bending along its length. It needs to be spliced between the supports and its not possible to locate the splice at locations of zero moment. The attached image shows the proposed splice detail. How would you go about designing the number of screws and screw spacing in this situation to transfer shear and moment across the splice? I know how to do a shear flow calculation, but doesn't that just resolve the shear component? What about bending moment?