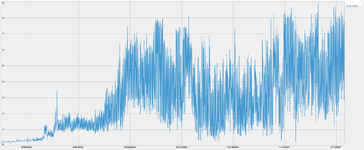

This video was what I was looking for.

Is this what you have?

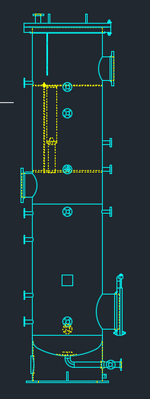

That looks to me like there are two liquid sumps. A knock out pot at the base and then a liquid pot in the main coalescing section.

Do you have a sectional drawing or P&ID of this?

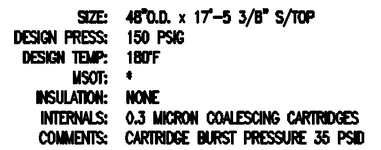

Do you have the specicif data sheet for these as it says burst pressure etc is customer specific.

a margin of 3 or 4 to the burst pressure for max DP seems to be common, so your 8 psi is pushing the boundaries. IMHO.

Maybe try reducing the height at which it pumps out both pots. The base pot may just be picking up slugs if it gets too full and the top pot adds to the DP.

Does the DP variance respond to liquid load?

These coalescers look fairly thick and have complex fibres so rapid changes in flow velocity or liquid load will induce flexing and lead to fatigue damage.

Also I know this is really stupid, but the flow does go from bottom to top / inside to out through the filters?