Are you confident on that number? The minimum displacement on those A10 motors is 10.6 cc/rev.

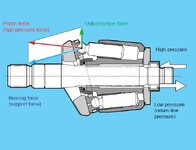

If this is the motor that is fitted, then the max speed is dictated by the mechanics of the swash plate and the reciprocal motion of the piston.

The statement on the data sheet is pretty clear:

▶ Operation above the maximum values or below the minimum values may result in a loss of function, a reduced service life or in the destruction of the axial piston unit. Bosch Rexroth recommends checking loads through tests or calculation/simulation and comparing them with the permissible values.

Adding a larger sprocket won't change the speed of the motor, it will only change the speed of the chain and increase the inertia of the rotating assembly. It also changes the forces acting on the motor. The motor has a specific power capacity based on displacement and pressure or torque and speed, with speed a derivative of displacement.

When you stop accelerating the motor, it will turn in to a pump as the inertia of the chain will try to drag the shaft. If you exceed the fill limits of the motor by running it above 5000 RPM, it will pull the slippers off swash plate and make a very loud and angry noise.

Confident on the pressure displacement and rpm figures- they came from a print sheet of the motor in its rebranded form. I suppose errors do occur but it's an official document. The R number was also provided with those specifications.

Where were you able to find out that it is an A10 series motor? I tried a couple times getting ahold of a rexroth rep but haven't had a return call yet.

Right, I hadn't mean to suggest that the sprocket would change rpm but the chain speed is the target trying to hit. 5000rpm on a 15 tooth sprocket gives a mid range chain speed. This is just for home use, not aiming for any record breaking sawing action...just want to stop cutting with a gas driven.

I am somewhat certain that this particular motor has a check valve between work ports built in? It's on the schematic as an internal part, but I could be mistaken. At a minimum, if a check between work ports was added externally or even along with a makeup check supplied by a tank source, this should alleviate any issues when stopping the motor? After doing some more figuring, I think I'm happy with staying below 5000 rpm and having a low chain speed if it means this motor will be usable.

If the rpm figure is correct flow should be limited to around 6.5 gpm or less...and I only have 3300 psi available so that is self fulfilling.

Some practical numbers compared to a large gas saw. Stihls largest chainsaw model MS881 is capable of ~ 7 ft lbs of peak torque at around 7500 rpm= 10 HP. A 5cc hydraulic motor should produce 12 ft lbs at 3000 psi....and if it runs at 5000 rpm- ~ 11.5 HP.

The MS881 typically can drive a 7 tooth sprocket- .404" pitch at 7500 rpm= 21,210 inch/min or 29 feet per second

The MS881 at 11,000 rpm on 7 tooth sprocket= 43 feet per second.

Since we have options and a mill and lathe, I plan on adapting a suitable 15 tooth sprocket to the hydraulic motor(and suitable width bar to match) - .404" pitch at 5000 rpm = 30,300 inch/min or 42 feet per second.

As far as force realized at the chain due to different sprocket sizes, I thought it to be helpful to express the relationship between the gas saw and hydraulic motor performance as torque/sprocket teeth since the diameter of the sprockets increases directly with tooth count, given the same chain pitch.

MS881- 7/7= 1.0

Hydraulic Frankenstein= 12/15= 0.8

My spaghetti throwing is almost over- the increased sprocket size will mean that the hydraulic version will have 20% reduction in performance vs the largest gas saw that Stihl produces. It seems like this should work at least to some satisfactory capacity? Are my hydraulic numbers somewhat correct? I don't expect any verification on the saw power figures.

I currently use a gas saw less than half the size of the example above, just for reference. I don't desire forestry harvester performance, and if it was equal to my much smaller gas model without having to manually use the saw and maintain an engine, it would be joy. Also for reference, the power source is a skid steer hydraulic system.

This is good discussion! I appreciate the talking points very much!