cheezypuff

Mechanical

- May 13, 2025

- 2

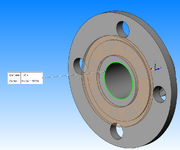

I'm using class 150 1 1/2" pipe raised face flange. It has an ID of 1.37" I was looking at the gasket from MMC. For 1 1/2", the gasket ID is 1 29/32". I understand the gasket OD should be between the raised face OD and bolts, but I don't understand why the gasket ID can't be a little bit closer to the pipe ID. In some ways, I'm tempted to get 1 1/4" gasket because the gasket ID is a little closer. Maybe the difference in ID is not that big of a deal after you compress it? Love to hear your thoughts.